Choosing a Food Machine Production Line

Manufacturing processes that use food materials require strict adherence to quality control and sanitation standards. Failing to meet those regulations results in fines and a loss of reputation as a manufacturer.

To maintain these strict guidelines, manufacturers must ensure the machinery in their facilities is up to standard and able to operate efficiently. This means scheduling routine maintenance work, including cleaning, inspection and testing, to keep the machines in good working order and prevent contamination from entering the products they produce.

Managing Equipment Downtime

Machine downtime is not only costly, it can affect the product being produced on the line. This is particularly true for food and beverage processors, since many of their products are eaten directly by people.

Routine maintenance is vital to the health and safety of workers and consumers, as well as the integrity of the product being produced. Regular sanitizing and cleaning is required to keep the food processing machinery free of bacterial growth, and to keep the machinery from being damaged by corrosive chemicals.

Compliance with CGMPs

A large part of the food processing industry is regulated by federal standards, such as the FDA's Current Good Manufacturing Practices (CGMPs). These strict rules can result in massive repercussions, and must be met to avoid fines and other penalties.

Keeping the machinery in good shape is a big part of ensuring compliance with these standards, as is making sure that workers are properly trained on the equipment and how to use it safely. By implementing a system of training and monitoring, manufacturers can minimize downtime and improve the health of their employees.

Automated assembly lines that are designed for food production come in a wide variety of designs and can be customized to suit any application. These lines can be equipped with mixers, homogenizers, dryers, chillers, fryers, feeders and separators.

Mass Production

Manufacturing on a larger scale often requires the use of larger, more complex machinery. This allows manufacturers to meet the demands of a high level of production in a short amount of time. It also provides scope for a company to create several different products on the same line, if they so choose.

Equipment Buying Process

The design of a new food line depends heavily on the type of equipment to be installed. Generally, consulting engineers work with a client to develop an efficient equipment specification that addresses performance, reliability and speed calculation methods, based on factory acceptance test (FAT) specifications.

Once a specification is developed, the consulting engineer works with a supplier's engineering staff to review and compare submittals and arrange for pre-testing of the major equipment vendors' machinery before it ships. This pre-testing is typically conducted at the factory.

During the construction of the new food line, the consulting engineer will coordinate with each vendor to verify that their equipment complies with the specified performance, reliability and speed calculations. This will help determine whether the new line is a success or not.

A new line can be an expensive investment, so the equipment should be carefully chosen to ensure it is a good fit for the production needs and that it will perform to expectations. In addition, the equipment should be sized properly to maximize efficiency and output, and it should be built from durable materials to resist wear and tear.

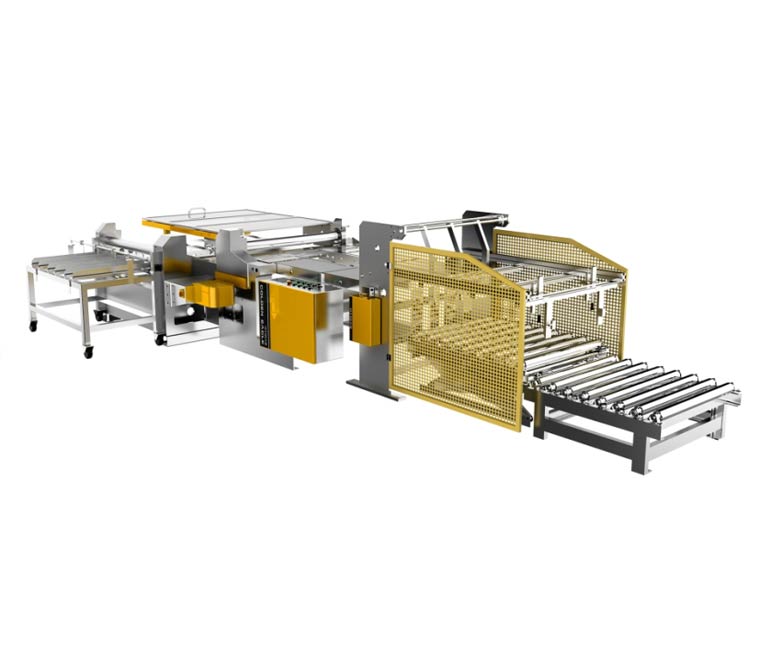

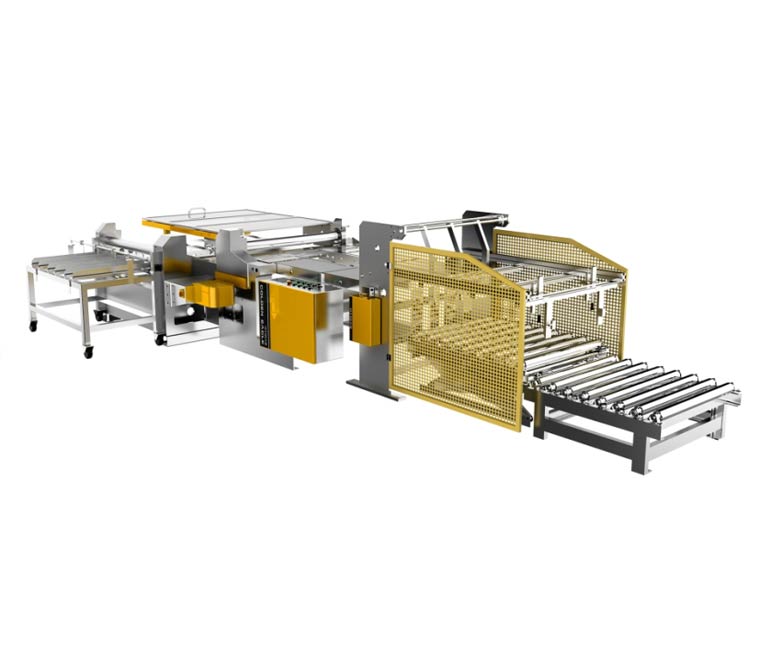

GT10A8 Automatic Tinplate Sheet Slitter Machine Auto Feeder

Metal Sheet Single Slitting machine for food can making. The circular knives are made from alloy steel, giving cutting effects and wearing resistance.

Model: GT10A8

Operation: Automatic

Application: Canbody Blanks Single Slitting

Can size: Various

Speed: up to 40spm