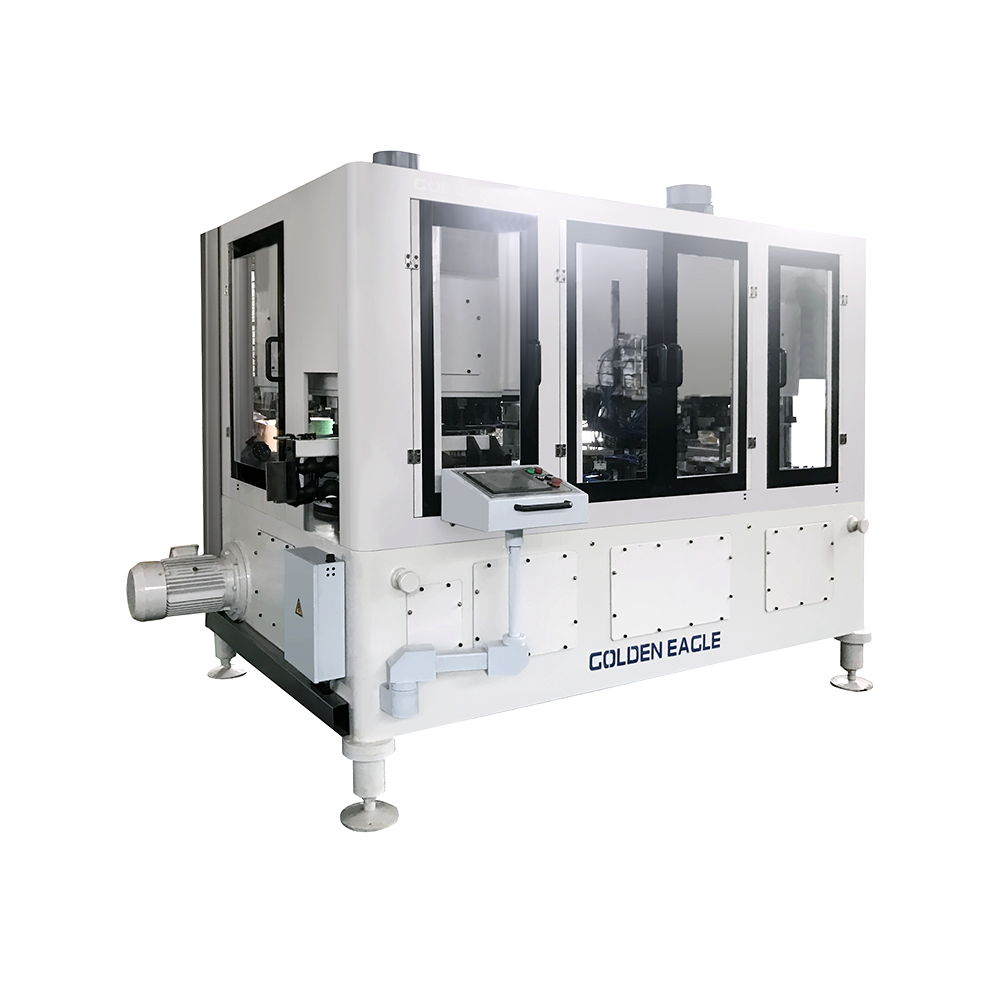

Introduction to Aerosol Can Making Machines

Aerosol can making machines are highly specialized equipment used in the packaging industry for producing metal cans that store pressurized products. These machines are widely applied in industries such as cosmetics, pharmaceuticals, food, and household chemicals. Since they operate at high speeds and involve metal forming, cutting, and welding, the potential for noise generation and exhaust gas emissions is a common concern. Understanding these environmental and operational aspects helps companies ensure safe and sustainable production practices.

General Operation of Aerosol Can Making Machines

The production process typically includes stages such as metal sheet feeding, body forming, welding, trimming, and surface treatment. Each of these steps involves mechanical and thermal energy, which may produce sound or by-products like fumes. For instance, welding can release gases, while high-speed cutting generates noise. The machine’s overall performance is closely tied to how effectively it manages these operational side effects.

Sources of Noise in the Production Process

Noise is one of the most noticeable factors in aerosol can manufacturing. High-speed stamping, cutting, and shaping of metal sheets often generate repetitive sounds that reach measurable decibel levels. The mechanical vibrations of motors, gears, and conveyors also contribute to background noise. Without adequate sound management, prolonged exposure can affect worker comfort and may even lead to health-related issues in extreme cases.

Typical Noise Levels of Aerosol Can Making Machines

The noise levels of aerosol can making machines vary depending on design, production speed, and installed sound-reducing features. While some machines operate at moderate sound levels, others can exceed thresholds that require hearing protection for workers. The following table provides a general overview of noise levels associated with different machine processes.

| Process Stage |

Typical Noise Level (dB) |

Notes on Source of Noise |

| Metal Sheet Feeding |

70–80 dB |

Motor and conveyor sound |

| Stamping/Body Forming |

85–95 dB |

Impact of metal shaping |

| Welding |

80–85 dB |

Electrical and arc noise |

| Trimming and Cutting |

85–90 dB |

Blade and vibration |

| Coating/Drying |

65–75 dB |

Ventilation and fans |

Exhaust Gas Emissions in Production

In addition to noise, exhaust gas emissions may occur in processes such as welding, coating, and drying. Welding can release small amounts of metal fumes and gases, while surface coating processes may emit volatile organic compounds (VOCs) if solvent-based paints are used. Drying ovens may produce heat-related emissions depending on the type of fuel or energy source applied.

Welding as a Source of Exhaust Gas

One of the core steps in aerosol can production is seam welding, which ensures the structural integrity of the container. During welding, localized heating of metal produces fumes that may contain oxides and gases. Modern machines often include fume extraction systems to capture and filter these by-products, reducing their impact on both workers and the environment.

Coating and Drying Stages

The internal and external surfaces of aerosol cans are often coated for protection and aesthetics. Depending on the coating material, especially solvent-based formulations, exhaust gases such as VOCs can be released. Drying ovens used to cure these coatings may also generate emissions, particularly if combustion heating is applied. These emissions are usually managed by exhaust systems, filters, and sometimes incineration units.

Control Systems for Noise Reduction

To address noise concerns, aerosol can making machines may be equipped with enclosures, dampers, and vibration isolators. Regular lubrication of moving parts also reduces mechanical friction noise. Additionally, production facilities often implement soundproof walls or partitions to minimize noise exposure to nearby work areas.

Methods of Controlling Exhaust Gas Emissions

Exhaust gas control is commonly achieved through ventilation systems, activated carbon filters, and thermal oxidizers. For welding fumes, localized extraction hoods are positioned near the welding point. In coating and drying sections, solvent recovery systems are sometimes used to capture VOCs and recycle them, which also reduces overall environmental impact.

Worker Health and Safety Considerations

Noise and exhaust gas both pose risks to workers if not properly managed. Prolonged exposure to high noise levels can cause fatigue or hearing issues, while inhalation of fumes may affect respiratory health. Therefore, personal protective equipment such as ear protection and masks are standard in facilities where aerosol can machines operate. Proper training on equipment use and safety procedures further minimizes risks.

Regulatory Standards and Compliance

Industrial regulations require manufacturers to manage noise and exhaust gas emissions. Standards such as ISO for noise levels and OSHA or local occupational safety guidelines for air quality are often applied. Compliance not only ensures worker safety but also avoids penalties or operational restrictions. Manufacturers of aerosol can making machines design their equipment to meet or exceed these standards.

Environmental Impacts of Noise and Exhaust Gas

From an environmental perspective, continuous noise can affect communities near production sites, while exhaust gases may contribute to air pollution if uncontrolled. Facilities address these impacts by implementing buffer zones, planting vegetation barriers for noise absorption, and adopting cleaner technologies to reduce emissions. Such strategies help balance production efficiency with environmental responsibility.

Maintenance and Its Role in Reducing Noise and Emissions

Regular maintenance plays an important role in controlling noise and exhaust gas. Worn parts often create excessive vibration and sound, while uncleaned filters or damaged ventilation systems reduce exhaust control efficiency. Scheduled inspections, timely replacement of parts, and calibration of emission control systems ensure that the machines operate within safe and acceptable levels.

Comparison of Different Machine Designs

Not all aerosol can making machines have the same environmental impact. Older models may lack advanced soundproofing or exhaust treatment systems, while modern designs often integrate multiple layers of protection.

| Machine Design |

Noise Control Feature |

Exhaust Gas Control Feature |

| Older Mechanical Models |

Basic insulation |

Limited fume extraction |

| Semi-Automated Models |

Partial enclosures |

Standard exhaust ventilation |

| Advanced Automated Models |

Full acoustic enclosures |

High-efficiency fume filtration |