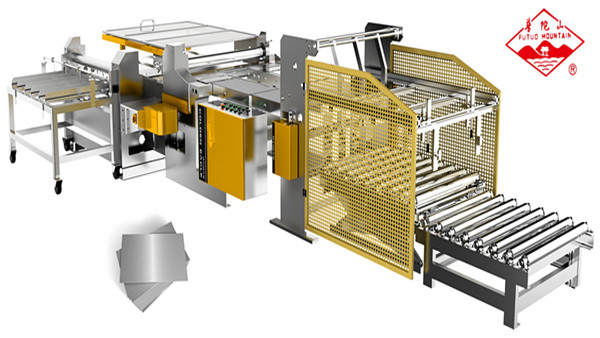

Process

deliver sheets pallet in place → Strong magnets separate sheets → Vacuum suck sheet → Rolling feeding sheet → Double sheet detection (excluding double sheets) →deliver sheet slowly by chain → The first cut → positioning → deliver sheet by chain → Positioning and feeding sheet → collection → inspection

Main technical parameters

Suitable max sheet size: 1140*1140mm

Suitable min sheet size: 500*700mm

Suitable sheet thickness: 0.1~0.4mm

Max feeding speed: 40 times per min

Max slitting speed: 1283 mm per second

Power: 6kw

Weight: 6000kg

Dimention: 6970*3040*1700mm

Structure Composition

1.Feeding mechanism

2.Delivering mechanism

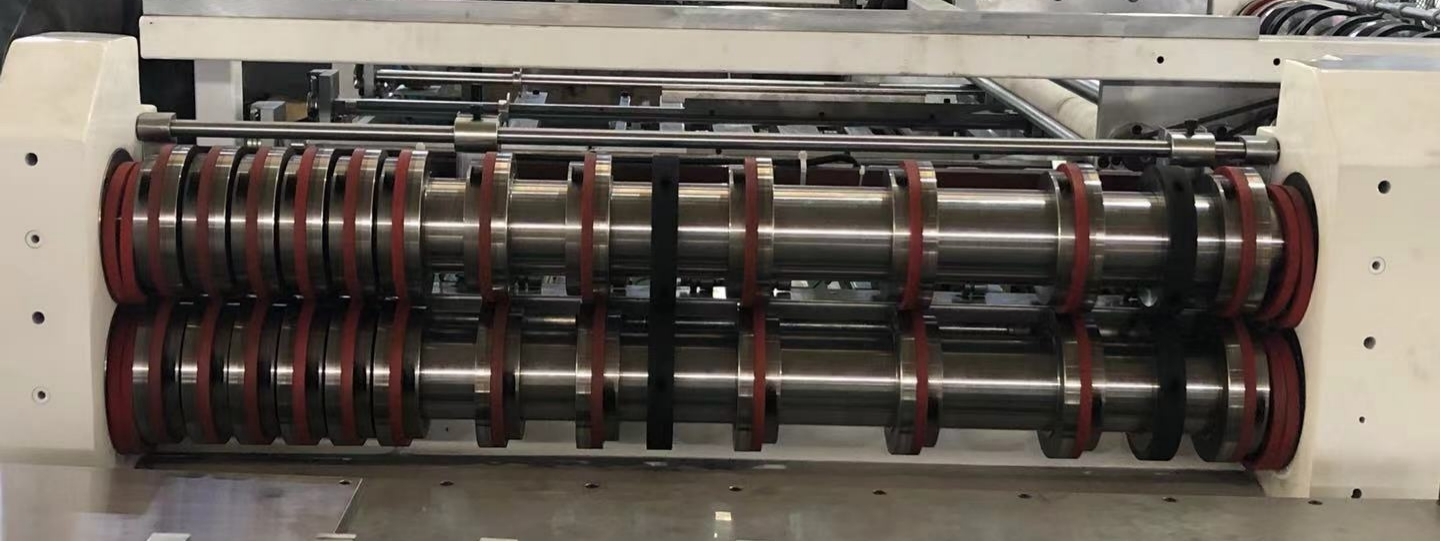

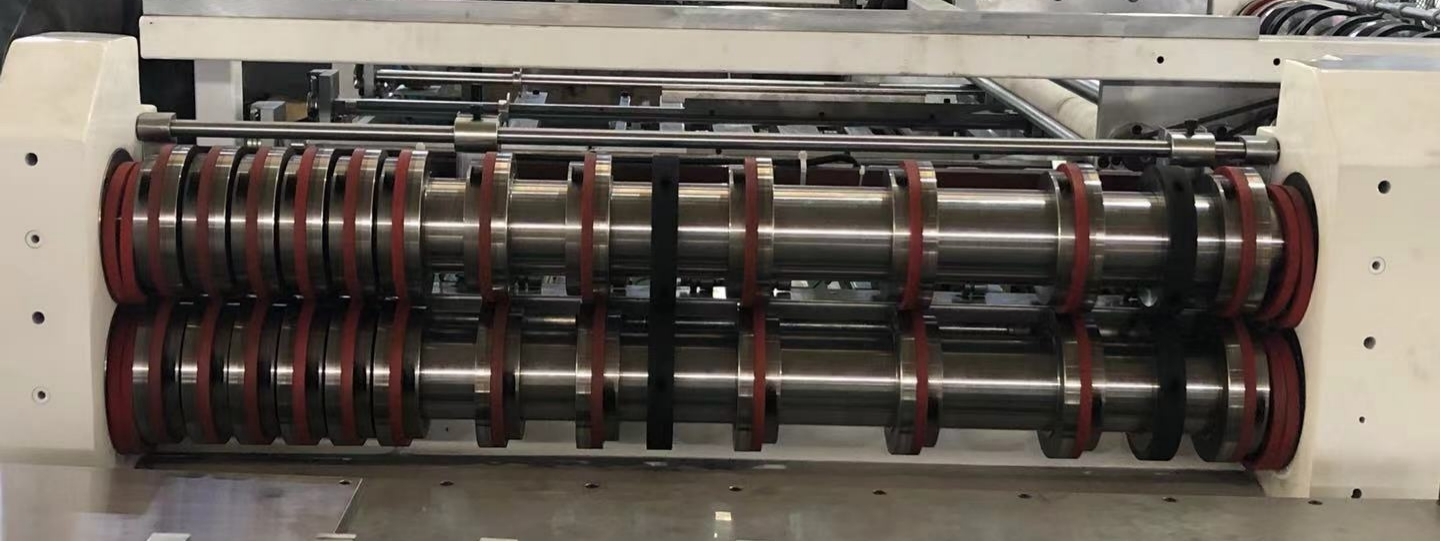

3.Wheel cutter mechanism

4.Collection device

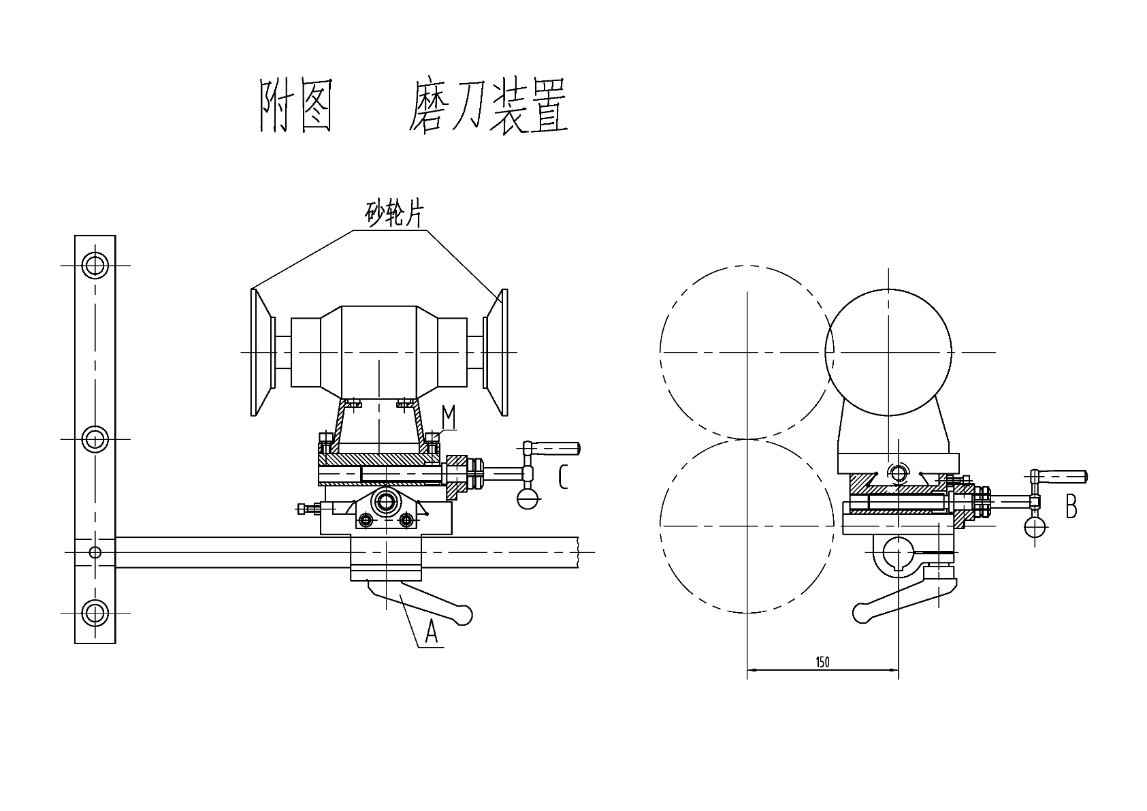

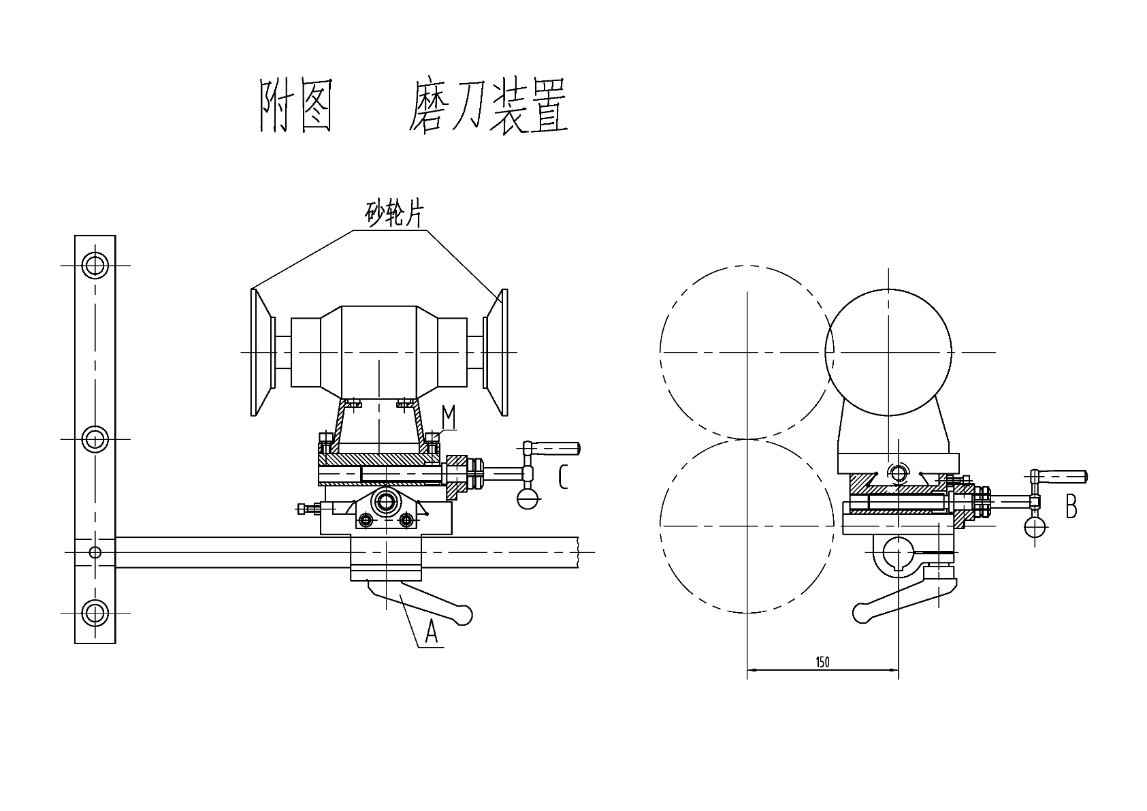

5.Knife sharpening device

Maintenance

1.Lubrication

The sprockets, gears, bearings, cams and tracks need to be lubricated with grease once a week. The gearbox needs to have its engine oil changed once a year.

2.Compressed air

User needs to drain the filter pressure reducing valve regularly according to the water content of its own compressed air.

Analysis of Common sheetdefective size

If the sheet material shows large burrs, inconsistent sizes at the front and back, "sickle bend" or "trapezoidal" phenomena, it may be caused by the dullness of the blade edge of the wheel, wear of the upper and lower wheel blades, too much sheets, or the gap between the upper and lower wheel blades being too large or too small. The solutions can be achieved by grinding the blade edge, replacing the wear-resistant wheel blades, and adjusting the gap between the upper and lower wheel blades.

The above is the product introduction of this machine. Thank you for your attention.

Helen-Xia

ZHEJIANG GOLDEN EAGLE FOOD MACHINERY CO., LTD.

https://www.goldeneaglecanmaking.com/

Email: [email protected]

Wechat / WhatsApp: +86 135 7563 0165