1. Importance of Precision in Can Manufacturing

In the modern packaging industry, the beverage can making machine plays a central role in ensuring that cans meet safety and usability requirements. Precision is essential because beverage cans, tin aerosol containers, and custom made cans must achieve strict dimensional accuracy to function properly in filling lines and sealing systems. Without reliable precision, cans may fail in sealing, stacking, or transportation. This is particularly important for products such as pressure aerosol cans, where slight deviations in thickness or diameter can cause risks in storage and usage. Therefore, precision in can production is not just a matter of efficiency but also a matter of consumer safety and brand reliability.

2. Core Components of a Can Production Line

A can production line typically consists of several key machines, such as the tin can machine, aluminum can making machine, molding maker machine, and cap molding machine. These machines are often supported by automated production equipment and inspection systems that help maintain consistent quality. Each stage of the line, from metal sheet cutting to molding and sealing, must be closely monitored. Food factory equipment and beverage manufacturing equipment integrate these machines to form a complete automated production system that ensures cans meet the standards required for beverage and aerosol packaging.

3. Role of Automated Production Equipment

Automated production equipment contributes significantly to controlling quality in can manufacturing. By minimizing manual intervention, it reduces the chances of human error. Automated systems in beverage can machines and tin can making machines can manage repetitive tasks such as forming, coating, and sealing with consistent accuracy. Additionally, the automation of pressure aerosol production ensures safer and more reliable handling of volatile substances. In modern factories, automated production systems can also connect to data-driven platforms that monitor real-time performance, making adjustments to reduce scrap rates and maintain uniform can quality.

4. Quality Monitoring Systems in Can Production

The inclusion of automated inspection equipment and quality monitoring systems is vital for ensuring that every can leaving the line complies with specifications. These systems inspect parameters such as wall thickness, seam integrity, coating uniformity, and dimensional tolerance. For example, when manufacturing beverage cans and tin aerosols, any deviation in seam sealing can compromise product safety. Quality monitoring systems not only detect defects but also provide statistical data that help in improving production processes. By integrating these systems into the can production line, manufacturers can identify issues at an early stage, minimizing waste and reducing the risk of defective cans reaching the market.

Quality Monitoring Systems in Can Production

| Inspection Equipment |

Monitoring Focus |

Application Scenario |

| Automated inspection equipment |

Surface defects, printing errors |

Beverage manufacturing equipment |

| Quality monitoring system |

Thickness, sealing integrity |

Tin aerosol & pressure aerosol |

| Sensor-based detection |

Cap molding precision |

Cap molding machine |

5. Materials and Metal Forming Control

The type of raw materials used plays an important role in determining the precision and durability of cans. Metal making machines are designed to handle aluminum and tin sheets with controlled thickness and hardness. For example, aluminum can making machines require precise calibration to ensure that the walls of the can remain strong while being lightweight. Similarly, tin can machines used for food and beverage containers must manage corrosion-resistant coatings to extend shelf life. Control over forming and molding processes ensures that the cans produced maintain consistent weight, thickness, and capacity.

6. Molding and Cap Forming Accuracy

The molding maker machine and cap molding machine are critical in shaping beverage cans and aerosol tins. A slight deviation in mold design or wear of the molding tool can lead to inconsistencies in can diameter, height, or sealing surfaces. To control precision, these machines often undergo regular calibration and are built with durable materials capable of withstanding high-volume production. In addition, advanced molding technologies enable more flexible production, allowing manufacturers to produce custom made cans with specific sizes and branding features without compromising on quality.

7. Integration of Beverage Production Line with Can Machines

In food and beverage industries, beverage manufacturing equipment and food factory equipment often integrate with can making machines to create a seamless beverage production line. This integration is important because the filling and sealing stages depend heavily on the precision of the cans. If the cans from the can production line do not meet the required specifications, the filling equipment may face issues in alignment and sealing. Therefore, precision control in can machines has a direct influence on the efficiency and safety of the entire beverage production line.

8. Role of Automated Inspection Equipment

Automated inspection equipment has become indispensable in modern can production. It checks every unit in real time, ensuring that cans comply with dimensional standards and safety requirements. For aerosol equipment, this includes testing pressure resistance, seam strength, and coating quality. Beverage can machines also rely on inspection systems to verify roundness, height, and uniformity. This allows manufacturers to identify quality issues immediately and make corrective adjustments before large quantities of defective products are produced.

9. Common Challenges in Maintaining Quality

Despite advanced systems, can manufacturers face challenges such as material variations, mold wear, and machine calibration issues. For instance, in tin aerosol production, small deviations in metal thickness can impact can durability. In aluminum can making machines, maintaining a consistent wall thickness while reducing material weight is a constant challenge. Automated production equipment helps in overcoming these issues by providing consistency, but preventive maintenance and skilled operators are still required to maintain stable quality.

10. Strategies to Improve Precision and Quality

To achieve reliable quality, manufacturers often implement several strategies such as regular equipment calibration, preventive maintenance schedules, and integration of data-driven monitoring. The use of advanced production line equipment with automated production systems allows for predictive analytics, which can foresee possible deviations before they occur. In addition, collaboration between material suppliers and equipment manufacturers ensures that the metal sheets used in beverage can machines, tin can making machines, and aluminum can making machines meet required standards.

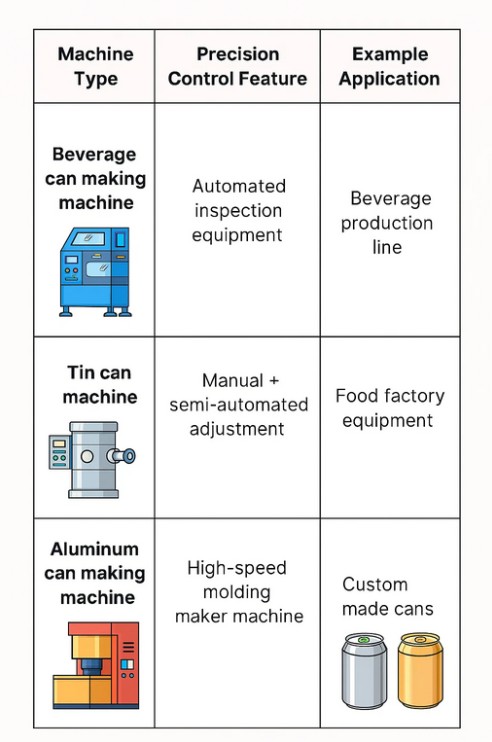

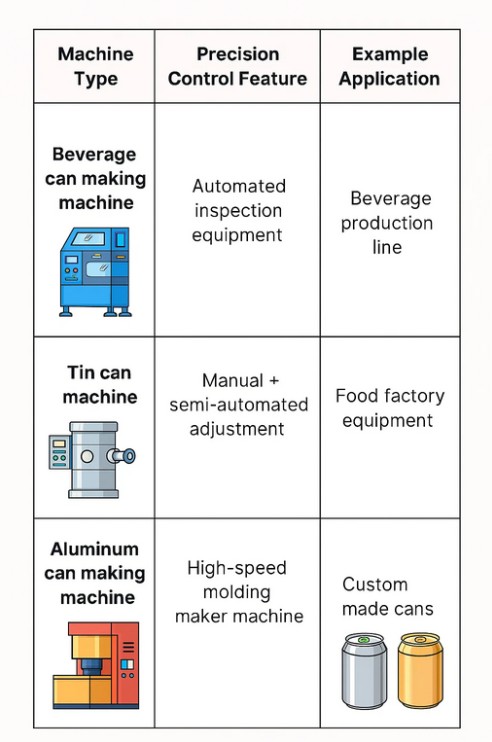

Comparison of Key Can Making Machines

| Machine Type |

Main Function |

Key Role in Quality Control |

Typical Application |

| Beverage can making machine |

Produces aluminum beverage cans |

Ensures lightweight but strong structure |

Beverage industry |

| Tin can machine |

Manufactures food-grade tin cans |

Provides corrosion resistance and durability |

Food and beverage packaging |

| Aerosol equipment |

Produces pressure aerosol cans |

Maintains safety standards under high pressure |

Aerosol products like sprays |

| Molding maker machine |

Shapes cans and container bodies |

Controls dimensional accuracy and consistency |

Beverage cans, custom made cans |

| Cap molding machine |

Forms caps and sealing components |

Ensures sealing compatibility with cans |

Bottle caps, aerosol closures |

| Automated inspection equipment |

Detects defects and measures accuracy |

Provides real-time quality monitoring |

All types of cans in production lines |

11. Future Trends in Can Making Precision

The future of can making machines lies in further integration of smart technologies. With the development of automated production systems and advanced inspection methods, beverage can machines and tin can making machines will achieve higher precision with lower energy consumption. Artificial intelligence may also play a role in predicting equipment wear and optimizing molding accuracy. In addition, the demand for custom made cans will require more flexible molding maker machines capable of adjusting to different sizes and designs while maintaining consistent quality standards.